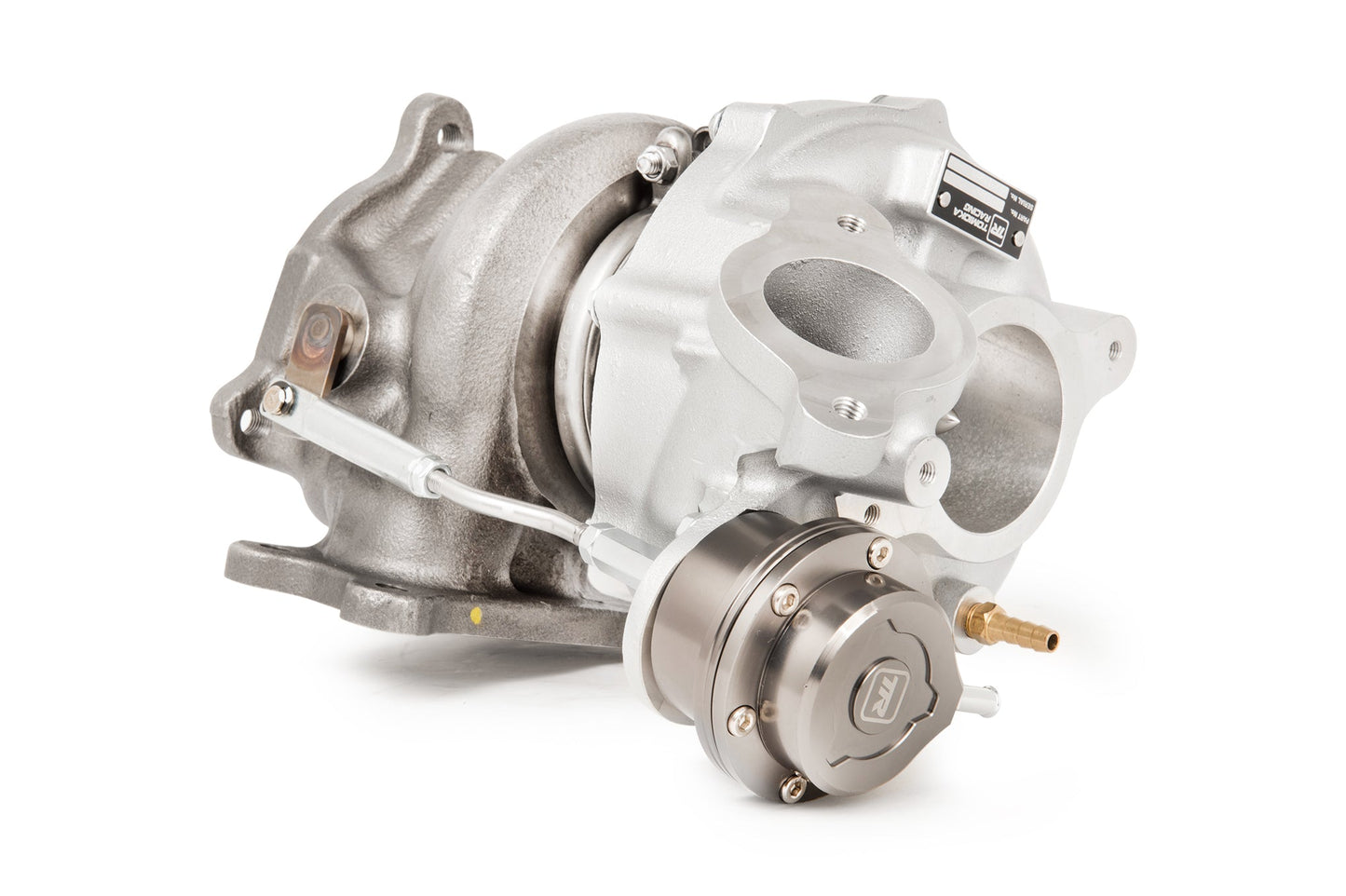

TR GTX29 DCBB Dual Ceramic Ball Bearing Turbocharger Stock Replacement for Subaru WRX 2015+ & Forester 2014+ FA20DIT (Gen II)

The next generation GTX29 turbo for the Subaru FA20DIT engine features an 8% larger turbine wheel compared to the previous version. In addition, the turbo also features a brand new dual ceramic ball bearing design from its previous generation. On the compressor side, the billet wheel is point-milled to improve airflow and reduce turbulence with the bullet locking nut. This turbo is perfect for users who are looking for a quick spool turbo, gain in the overall power band, and top-end power for the Subaru FA20DIT turbo. All necessary fittings and gaskets are included in the box to make the installation process painless.

|

Bearing Type: |

Dual Ceramic Ball-Bearing |

|

Flange Type: |

Standard Subaru 5-Bolts |

|

Compressor / Turbine Wheel: |

72 mm / 61mm |

|

Turbine Housing: |

10cm2 |

|

Actuator: |

1.03 bar / 15 psi |

|

Horsepower: |

600 HP |

| OEM Replacement |

- Replace OEM # 14411AA880 / 14411-AA881 - Replace OEM # 14411AA880 / 14411-AA881 |

Features:

- Angular Contact Dual Ceramic Ball Bearing

- Point-Milled Compressor Wheel

- Larger Turbine Wheel

- 100% Bolt-On

- Bullet Locking Nut

Applications:

-

2015+ Subaru WRX

-

2014+ Subaru Forester (FA20DIT)

-

2012+ JDM Subaru Legacy 2.0GT DIT, 2014+ Subaru Levorg and 2015+ JDM Subaru WRX S4

-

2014-2018 USDM Subaru Forester badged as Forester XT

-

2014-2018 JDM Subaru Forester badged as Forester XT

-

2015+ USDM Subaru WRX

Kit Contents:

- Turbocharger

- Gaskets

- Hardware Kit

- Motul 300V Competition 2L

Frequently Asked Questions:

- Is this a bold-on turbo? Absolutely, this is a blt-on turbo that fits seamlessly with the existing hardware. No modifications to the piping are necessary; it will fit perfectly.

- What is the spring rate on the actuator? It's set at 15 PSI. The turbo comes equipped with an adjustable wastegate actuator for precise control of boost pressure delivery.

- Is an aftermarket solenoid necessary? No, it's not required. The stock solenoid is sufficient for the task. If you are aiming for incremental performance gains with a faster boost cueve, you may consider using our high precision, German-made boost solenoid. Our solenoid not only meets but surpasses factory specifications. We take pride in having one of the best boost solenoids on the market.

- What's the maximum boost level? 32 PSI

- Do I need exhaust manifold? If you are seeking additional performance and power, our turbo is ideally paired with an aftermarket manifold. This combination enhances spooling and increases high-end horsepower and torque.

Wastegate actuator spring choice: 1.1 bar vs 1.3 bar (what customers need to know)

What the spring actually controls (and why it matters)

On a pneumatic internal wastegate, the actuator spring sets your gate pressure (often called base boost): the boost level where the wastegate starts to open because boost pressure overcomes spring force. Haltech describes it simply: changing spring pressure changes the default boost pressure, and when boost exceeds spring pressure the valve opens and begins regulating boost.

Choose 1.1 bar (16.1 psi) / Red if:

You want a lower boost map (street/traction/valet) around the mid-teens. Remember: you can’t go under the spring.

Your normal target boost is roughly 18–22 psi and you want good controller authority and flexibility.

You’re building a setup where drivability and multiple boost modes matter (daily + weekend map).

Choose 1.3 bar (19.1 psi) / Silver if:

You will not run low boost—your “low boost” is still ~19 psi or higher. (If you need 15–17 psi sometimes, don’t pick this.)

Your normal target boost is roughly 22–28 psi and you want:

less “work” from the boost control system to hit target, and

typically better resistance to the wastegate being pushed open early (especially in higher load / backpressure situations).

There are two different “maximum boost” questions people ask:

1) Maximum boost your boost control can hold consistently

Using the GFB rule-of-thumb (target boost ≤ ~2× gate pressure) :

With a 1.1 bar / 16.1 psi spring, the “control stability ceiling” is roughly ~32 psi (2 × 16.1).

With a 1.3 bar / 19.1 psi spring, the “control stability ceiling” is roughly ~38 psi (2 × 19.1).

Reality check: that does not mean “safe to run 32–38 psi.” It means beyond ~2× gate pressure, boost control tends to get inconsistent because the actuator isn’t receiving enough meaningful reference signal for correction. GFB explains that once you go beyond double, boost control becomes less stable and more affected by variables like RPM/load/backpressure.

2) Maximum boost your turbo/engine can safely run

That’s not spring-limited. It’s limited by:

turbo efficiency and speed/heat,

fuel quality and knock margin,

intake temps/intercooling,

exhaust backpressure,

engine/clutch/trans limits,

tuner strategy.

FAQ:

Can I run less boost than the spring rating?

No. Spring pressure is the lowest boost level you can reach.

Does a stiffer spring automatically mean higher peak boost?

Not automatically. It mainly raises minimum boost and changes how the wastegate behaves. Boost above spring comes from the control strategy.

Why do people say “don’t exceed 2× the spring”?

Because boost control gets less stable as target boost gets too far above gate pressure; beyond ~double you tend to lose correction authority.

What spring gives the best spool and boost stability?

A spring that puts gate pressure about 10–20% under your target boost is a strong general guideline for best performance.